01 September 2022, Mumbai

The days when a consumer would simply choose a product based on its quality are long gone. There was a time when domestic market competition was comparatively relatively limited. The conventional wisdom cliche is," The world marketplace is continuously changing and so is the demand of people changing".

However, as globalization took hold in recent years, the level of competition and quality consciousness increased. Consumer needs gradually increased due to the constant advancement of technology and application standards. And to meet that standard, producers must add something to their goods to increase the value of those goods.

A product must be able to include additional features, and this has brought the market in the present day to a point where it appears very challenging for a manufacturer to market his product until he offers consumers something fresh, which not only rewards him for his innovative idea but also tempts him with a significant increase in profit.

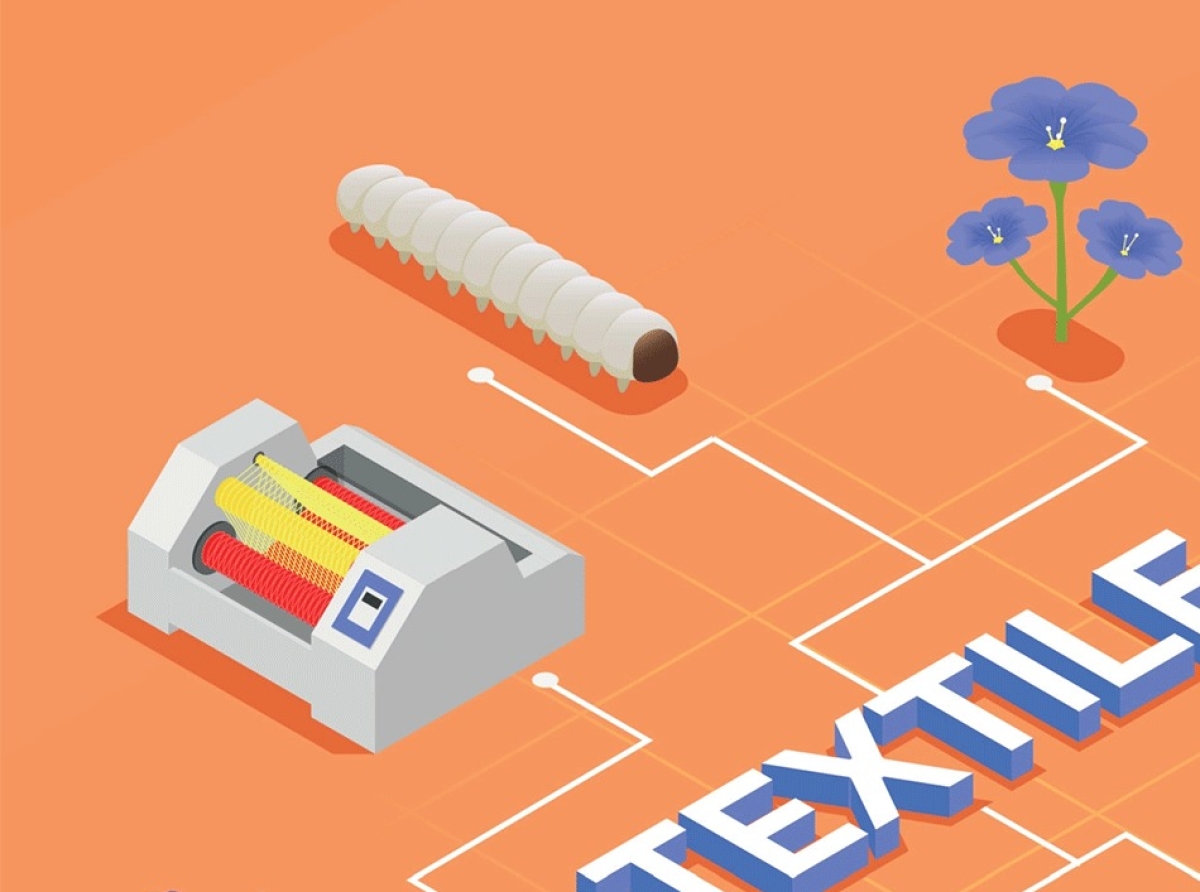

This desire to create something innovative to boost profits, get a more significant market share or satisfy a craze might likely be described as adding value to textiles.

No gainsaying that without value addition finishes of textile products today it is no more viable/feasible to sustain in the given fiercely competitive global marketplace. In the same direction, the global apparel industry is also started to undertake new initiatives with all new zeal factoring in increased competition from other corners.

Change is the only constant

The need for individuals is always shifting, much like the global marketplace. Everyone wants to see some change. i.e., something fresh & different. Change must be implemented successfully and effectively in the market.

Through the use of this paper, we have made a sincere effort to present you with a thorough analysis of the value addition performed in the current finishing industries such as textiles by some of the new value addition processes in chemical finishing and mechanical finishing that have exploded this industry with opulent value added finishes and forced manufacturers to disregard all those antiquated finishing treatments that previously ruled this Industry.

One Research gate study mentions," Imagination, innovation, and technology take textiles to the extreme specialty applications".

Technology has limitless uses in industrial composites, electronics, medical apparel, protective gear, and performance outerwear and equipment. Super performance fibers most likely to replace metal parts for augmented functional properties are very evident.

The method produces breathable, soft, and compressible water and wind protection textiles for sportswear and equipment. Thermally conductive, conformal materials with exceptional handling properties are used in semiconductor and electronics applications, as well as flexible, lightweight reinforcing textiles with outstanding adhesive properties for the aerospace and automotive sectors.

As per one Research gate study," Beyond the basic demand, our appetite for smart T&A and our quest for comfort and a quality lifestyle seem to drive the growth of the T&A/T&C sectors from country to country".

Need of the day

The Indian textiles sector needs on a sustained basis to rewire, refocus, reimagine and concentrate on enduring sustainable value addition as nothing less than that shall do. There are no areas where water may hide, thanks to the encased fibers and the polymer barrier between the fiber bundles. As a result, the textiles are very windproof, water resistant, and breathable.

A sour point still remains is, " Unsustainable textile industry growth with the mindless impact it has on environment". As it is no more a well-kept secret that the Textile sector is a water-thirsty industry wherein exponential amounts of water are used throughout textile manufacturing processes. According to the Ellen MacArthur Foundation, textile production uses around 93 billion cubic meters of water annually — the equivalent of 37 million Olympic swimming pools.

The popular acceptance today is that textiles also maintain their softness and flexibility in cold temperatures since there is no coating. Stretch fabric is a given, especially in women's apparel. For "body fitting apparel/clothes and figure regulating reasons whereas stretch yarns and fabrics are employed,".

Therefore, an electrometric core is added to basic yarns during spinning to generate core spun yarn, i.e., weaving stretch textiles for bottom weights and even shirting fabrics is no less than conspicuous value addition. Nowadays, lifestyle apparel/clothing impacts market segments that were once stable, like basic suits and shirts.

Trading economics one reports reveals," Textiles and clothing (% of value added in manufacturing) in India was reported at 8.5792 % in 2019, according to the World Bank collection of development indicators".

The general trade experts' observation & reflection is that" the textile industry per se is unable to tap its potential in accordance with its inherent capacity".

Join our community on Linkedin

Latest Publications