19 November 2022, Mumbai:

High inflation, price rise of raw materials and GST have been hitting hard Surat’s synthetic textile industry. The industry recorded a 60 per cent decline in business this Diwali compared to last year during the same period.

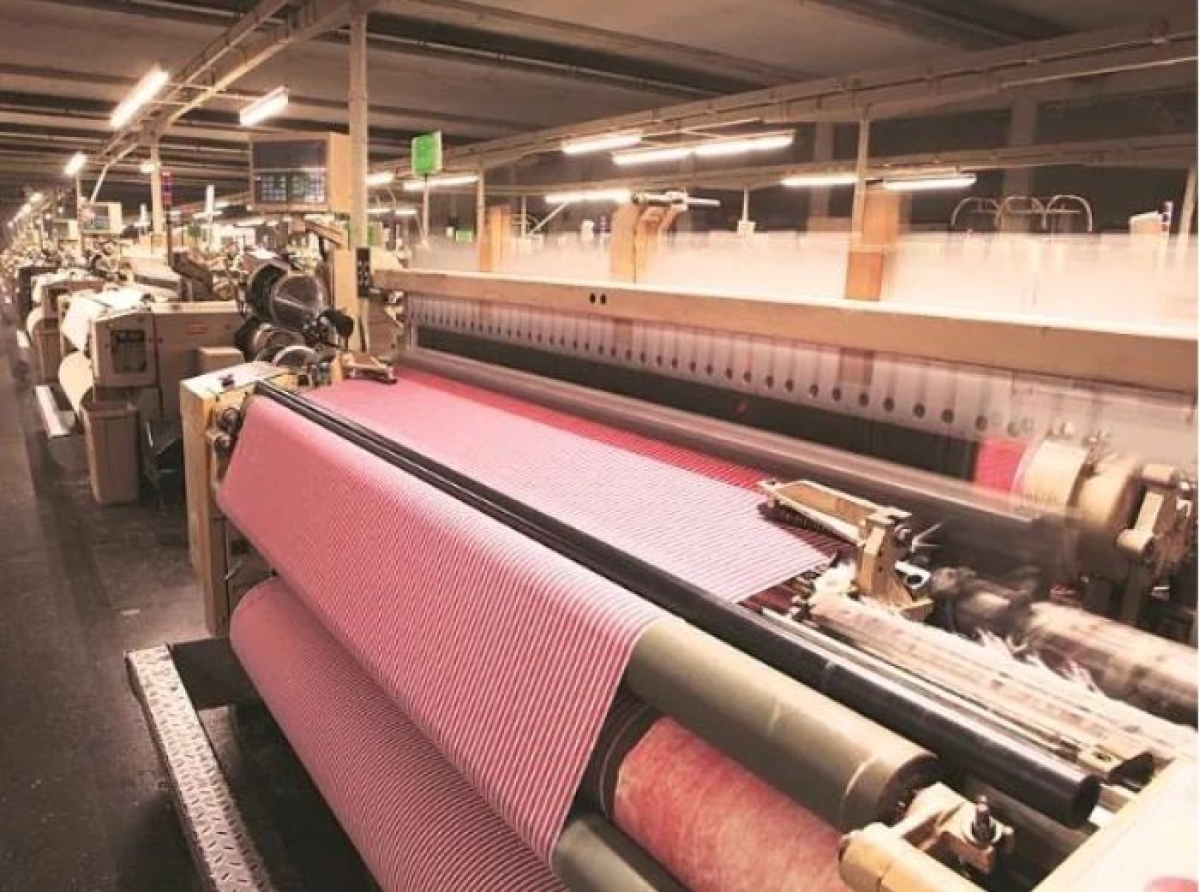

Surat’s synthetic textile industry comprises various verticals like spinning polyester yarn and weaving grey clothes, which are then dyed, processed and embroidered. Textile traders buy the grey cloth woven at power looms and get them dyed, processed, and the embroidery works done before selling them to wholesalers across the country. But now traders are abandoning the work to shift to other sectors because of the new tax regime, skyrocketing prices and lesser returns.

The meltdown in the textile sector has caused a massive lay-off of labourers. Of the one lakh labourers, around 35,000 have already lost their jobs. And if this continues, more people will be left jobless. Around 45,000 to 50,000 multi-headed computerised embroidery machines in Surat are operated by the same number of labourers who work in two shifts. Night shifts in embroidery units have completely stopped because of a fall in orders.

The industry is fast losing its sheen. Every manufacturer used to have bulk orders since Diwali (which traders and manufacturers consider the beginning of their new business year). The workload was such that they had no time to meet their families.

But this year, even after almost a month since the festival, most factories are shut because they do not have work from traders. Where one machine was manned by at least two workers, because of a fund crunch two machines are handled by one worker.

GST effect

The rollout of GST was a challenge. Traders have to pay taxes and account for the same at each stage. Unlike in the pre-GST era, a sole entrepreneur, working informally cannot do so. The predominantly informal business sector of synthetic fabrics bears the brunt of the new tax system. While the aim of GST is to boost tax revenues and formalise India’s economy, the reality is Surat’s cluster is unable to pay these taxes and remain competitive. Structure of Surat’s cluster

Two value chains co-exist in the Surat cluster. The first comprises thousands of small units engaged in garment manufacturing — some units make yarn and others weave it into the fabric. Many of them print, stitch and embroider the garment. More than 70,000 textile traders play a pivotal role in this arrangement.

They take orders from textile and apparel/garment (T&C) sellers and lead the consignment from unit to unit along the manufacturing process. It is a competitive value chain where thousands of small businessmen, who are operating their units with the help of migrant workers, compete with each other for business.

The other value chain is integrated and organised. It has large companies which do everything — from weaving to post-production in-house. But not even ten such firms exist in Surat.

Most units in the cluster operate in the disaggregated value chain. GST has impacted both of these value chains. Profit margins have come to an all-time low because of the hike in prices of raw materials and stagnant rates of the consignments.

The textile cluster in Surat has been hit in terms of tax rates and structure since everything from raw materials to finished products is attracting a different tax rate.