14 June 2022, Mumbai:

The apparel sector in India, often known as the ready-made garment business, has shown consistent expansion in recent decades.

Many of India's top garment manufacturers have also become some of the world's leading clothing suppliers, achieving great success in critical areas of clothing manufacturing, exports, sales, and employment for India's textiles sector in recent years, as well as contributing significantly to the country's GDP growth.

ALSO READ Smart Garments for Smarter Living

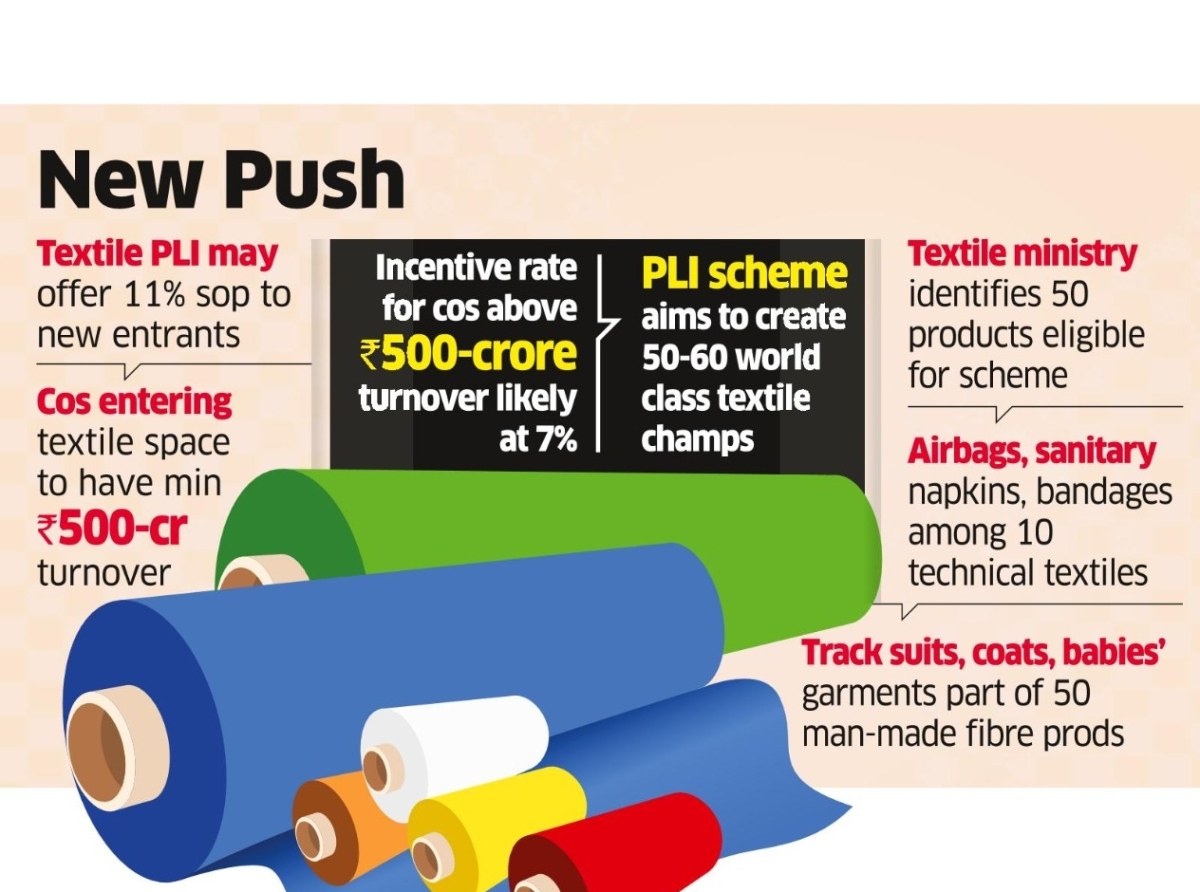

According to McKinsey's FashionScope, India's apparel and garment market will be valued at more than $59.3 billion in 2022, maintaining its position as the world's sixth-largest clothing manufacturer. The expanding population of people with higher incomes and significant government backing is driving market expansion. According to reports, the targeted population's aggregate income is predicted to treble by 2025, resulting in substantially more robust demand in India's garment manufacturing business.

The garment sector in India today employs over 13 million people, making it the country's largest employer. In recent decades, many of India's largest apparel factories have also become essential providers of ready-made garment items for the worldwide market. Adopting new technologies such as machine learning and cut and sew robots will likely significantly influence the global garment manufacturing industry through 2025.

RELEVANT NEWS Indian Apparel Sector: Top 10 Valued Brands

Clothing producers are constantly seeking for natural ingredients to lower their carbon footprint. Therefore the growth of sustainable dyeing will have a growing influence.

1. KPR Mill -

KPR Mill Limited produces yarn, knitted grey, colored fabric, and readymade garments and is one of India's largest vertically integrated clothing manufacturing enterprises.

With an annual capacity of 95 million pieces, the firm boasts one of India's largest garment manufacturing plants. It has also erected windmills in Tamil Nadu to create green electricity for captive use, which would fulfill 75 percent of the state's power needs. KPR Mill stock prices will be a constant topic of conversation in 2018, with windmill growth at the forefront.

RELEVANT NEWS Apparel brands owe $22 billion to supplier factories

2. Bombay Rayon Fashion Ltd -

Bombay Rayon Fashions Ltd is a vertically integrated textile and apparel firm that produces various textiles and garments in state-of-the-art manufacturing facilities. Besides being India's largest shirt maker, Bombay Rayon Fashions Ltd now employs over 38,000 people and produces over 90 million garments annually. Its high employment has been a continuous contributor to India's GDP.

3. Raymond Ltd -

Raymond is one of the top fabric producers and largest garment manufacturers in India, and a capacity of 38 million meters in wool-blend textiles and a market share of over 60%, ranking among the first three fully integrated makers of worsted suiting in the world. Raymond may be the only firm in the world with a broad product selection of approximately 20,000 designs and colors of suiting fabric to fit any age, event, and style. Raymond produces high-value pure wool. Raymond's products are exported to more than 55 nations, including the United States, Canada, Europe, Japan, and the Middle East.

RELEVANT NEWS India’s RMG Exports: 22.08% growth during April-May’22-23

4. Vardhman Textiles -

Vardhman Textile is an Indian textile manufacturer based in Vardhman. This Vardhman Group subsidiary was created in 1965 and has grown into India's largest textile manufacturer, with annual sales reaching $1 billion. Vardhman is an Indian yarn, greige/processed fabric, acrylic fiber, and other product maker and trader.

In India, the firm has 22 production units spread over five states. Since its establishment, Vardhman Group has evolved into a worldwide business powerhouse with operations in India and 75 other countries. It is engaged in the production of yarn, cloth, and acrylic fiber. Vardhman has a sound business plan and a significant market share as India's second-largest textiles firm by sales.

RELEVANT NEWS How Will The Future Smart Apparel Factories Look!

5. Trident -

Trident Group has become one of the world's largest integrated home textile firms, with goods sold in over 100 countries. The firm is a prominent yarn spinner in India and a world-class terry towel maker. As a result, Trident is India's leading manufacturer and exporter of cotton terry towels and other domestic textiles, chemicals, and captive power.

6. Page Industries -

Page Industries Limited (PIL), situated in Bangalore, is a subsidiary of JOCKEY International Inc. (JIC). In India, Sri Lanka, Bangladesh, Nepal, and the United Arab Emirates, it is the only licensee of the JOCKEY® brand.

Page Industries has been awarded the exclusive license to manufacture, sell, and distribute Speedo items in India by Speedo International Ltd. JOCKEY is the company's flagship brand and a market leader in the innerwear area. Page Industries and JOCKEY's unique work has resulted in several firsts in the innerwear industry.

RELEVANT NEWS Jockey India expands 'offline footprint' despite 3X growth in online sales

7. The SEL group -

SEL, an Indian textile company, is one of the largest vertically integrated textile companies in the country and the globe. From spinning and knitting to generating value-added goods like terry towels and ready-made clothing, the company's facilities in Punjab, Haryana, Himachal Pradesh, and Madhya Pradesh serve a diverse spectrum of customers.

SEL is a significant yarn and thread supplier to the European and American markets.

Arvind Ltd - Arvind Ltd was established in 1931. Ahmedabad is the company's headquarters. Knits, retail, woven, telecom, advanced material, agri-business, and other items are available from the corporation. Through its statewide retail network, the firm owns brands such as Flying Machine, Newport, and Excalibur, as well as licensing foreign names such as Arrow and Tommy Hilfiger. It is one of India's top ten garment and textile companies.

_large.jpg)

9. Dollar Industries Ltd -

Dollar Industries Ltd was established in 1972. The business creates and sells clothing. Men's and boys' innerwear, nightwear, winter care, trousers, socks, and other relevant accessories are available from the company.

Dollar Industries Limited has established itself as one of the major brands in the hosiery industry, with a 15 percent market share and a large proportion of textile exports in the Indian hosiery market. It is one of India's top ten garment and textile companies. Subscribe to Fundoodata subscription plans to acquire additional information about the organization, such as critical executive details, turnover, and personnel count.

10. Nahar Industrial Enterprises Ltd -

In 1983, Nahar Industrial Enterprises Ltd was established. It's a firm that makes textiles. Sugar and Textile are the two segments in which the company works. Yarn and cloth are available under the Textile section.

Yarns include 100% cotton yarns, 100% cotton colored yarns, compact spun yarns, 100% blended yarns, 100% polyester yarn, industrial yarns, open-end yarns, open-end slub yarns, specialty yarns, Eli twist yarns, core-spun yarn, and vortex yarns, as well as textiles such piece-dyed yarn-dyed and prints. A variety of mixes are also available from the company.

Join our community on Linkedin

_large.png)

_large.jpeg)

2_large.jpeg)

-apparel-industry_large.jpg)

_thumbnail.jpeg)

1_large.jpeg)

_large.jpg)